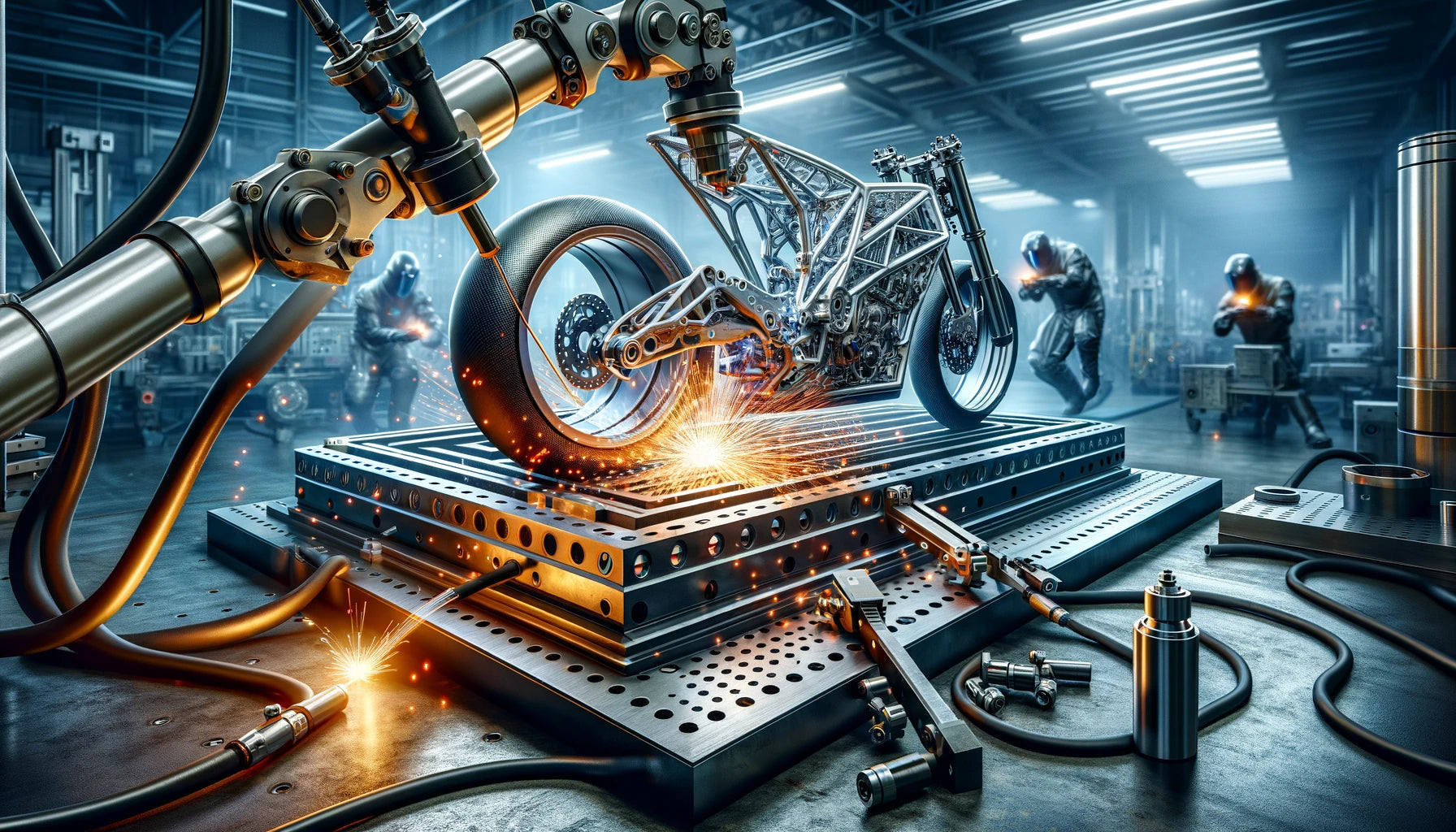

Essential Tooling Solutions in Automotive & Motorsports Engineering

IIn the realm of automotive engineering and motorsports, precision, efficiency, and innovation are paramount. Tooling, a critical element in manufacturing and maintenance, encompasses the selection and application of the right equipment to meet these stringent demands. Specifically, in automotive manufacturing and garage setups, tooling is categorized into jigs and fixtures, each serving a distinct purpose to enhance production quality and speed.

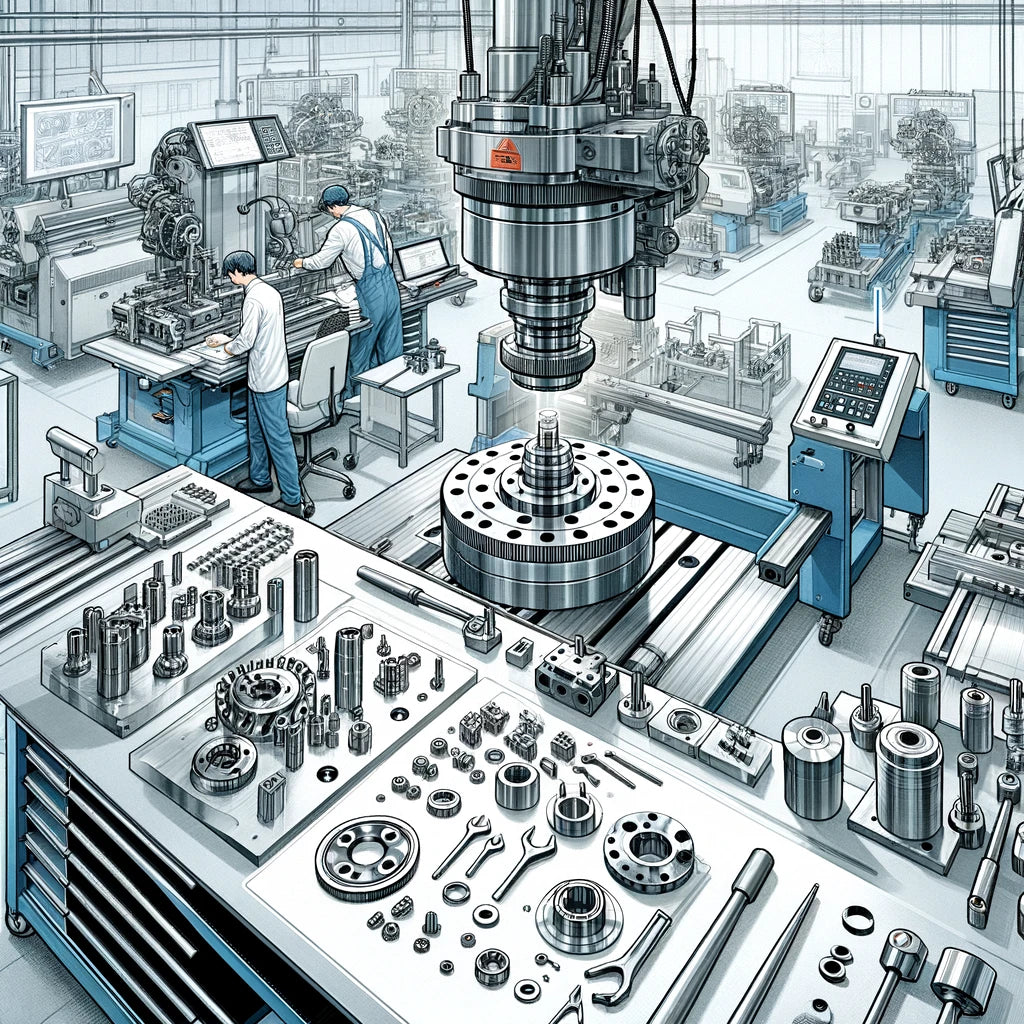

Jigs: Precision Guides for Cutting Tools

Jigs are invaluable in repetitive machining operations, where precision and repeatability are key. These devices guide cutting tools, ensuring that each component produced meets exact specifications. For instance, in the production of engine parts or chassis components where multiple drilling operations are required at precise locations, jigs eliminate the need for manual marking and alignment, significantly reducing production time and enhancing accuracy.

Types of Jigs in Automotive Manufacturing:

Template Jigs

Fundamental tools for drilling operations where a template ensures consistent hole placement across components.

Plate Jigs

Ideal for large automotive parts, incorporating drill bushes for accurate hole spacing.

Channel Jigs

Simplified jigs for quick operations, facilitating easy placement and removal of components.

Diameter Jigs

Designed for radial operations on cylindrical parts, crucial for components like axles or drive shafts.

Leaf, Ring, and Box Jigs

These specialized jigs cater to specific automotive components, enabling machining from multiple angles or on parts with complex geometries.